Product description:

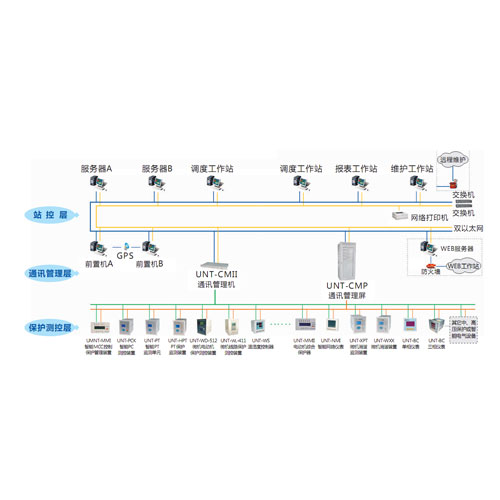

The Electric Automation System (ECS) of the power plant is a new integrated automation product developed to promote the development of automation technology for power plant electrical systems. The system is based on the technical essence of computer protection, monitoring and integrated automation products for many years, using a layered distributed architecture. On the advanced computer control technology and communication technology platform, the monitoring, control, regulation, protection and telecontrol functions of the generator set, plant power and network control parts are realized. The system has the function of network communication with the power plant DCS system, thereby realizing the integration of the electrical automation system (ECS) and the machine furnace distributed control system (DCS), and finally making the control of the furnace, machine and electricity of the power plant become a unified and coordinated whole. In order to comprehensively improve the automation level of the power plant, the safety and reliability of the power plant operation are improved.

Features:

? Monitor, control, protect and manage all electrical equipment. Changed the situation that only a few important electrical quantities were connected to the DCS, realizing the automation of the electrical system and improving the operation and management level;

The microcomputer protection, measurement and control device and other special automatic devices used in the system are selected from the principle of advanced products and reliable on-site operation. They are not restricted by communication functions and can be operated independently to ensure the safety and stability of the system.

The power consumption system of the factory uses a microcomputer-based protection and measurement integration device, which can be distributed in various electrical intervals, truly achieving layered distribution and high system reliability;

? Make electrical and DCS control levels consistent and coordinated development. The electrical integrated automation system (ECS) is well interfaced with the DCS system of the power plant to achieve a seamless connection;

? Control operations can be performed at the DCS operator workstation or at the Electrical Automation System (ECS) operator workstation after authorization by the DCS system;

When the network communication method is adopted between the electric integrated automation system (ECS) and the power plant DCS system, the amount of information exchanged between the two is not limited, and a large number of control cables and transmitters can be saved;

?Communication control machine has large information capacity and good openness;

?Monitoring software has powerful data processing and information management capabilities, real-time and friendly human-machine interface;

? The system has clear structure and flexible configuration, which is convenient for operation and maintenance.